Capabilities at the core of our business are wire straightening and cutting to length, wire pointing and chamfering, and cutting wire to a tight tolerance final length. We utilize custom engineered and built machinery, some of which were patented in 1906. Our processes provide precision at an affordable price. For further information on how John M. Dean Co. can help with your next project, or to learn more about our capabilities, contact our sales team today!

Using 15 highly precise straightening and cutting machines, we can produce pins and straightened wires ranging from: Diameters 0.015″ through 0.375″ (0.4mm – 9.5mm) Lengths 0.125″ up to 96″ (3.0mm – 2400.0mm) The most common materials we process are mild or low carbon steels such a 1008/1010, high carbon alloy steels like 1060/1080, and stainless steel such as 300 series and 400 series.

If your application requires another type of material contact our sales team for more information, or to determine if John M. Dean Co. can meet your material requirements. While there are endless possible uses for straightened wires, some common uses are bearing shafts, precision and production dowels, assembly mandrels, hinge pins, rivet blanks, rollers for bearings, blank length stock, retention pins, and many more.

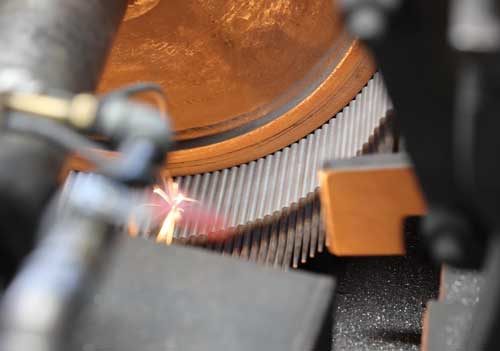

Our custom machinery offers high-throughput precision for any wire end profile you can imagine. We offer various types of taper profiles and chamfer options. Whether you’re looking for a gradual straight taper to a fine point, or a barrel taper to a setpoint (such as those found on common tools like punches or large picks) or anything in between, our experienced production team has you covered. With 16 grinding machines of differing configurations we’re able to accomodate many challenging taper profiles with ease and speed.

Cutting carbon steel and stainless steel wires can be difficult without the right tools for the job. At John M. Dean Co. we engineered our cutting machinery over 100 years ago to be the most reliable and robust there is. To this day we pride ourselves on our unmatched cutting capabilities. Our 11 pin cutting machines can cut 0.015″ diameter wires through 0.375″ without skipping a beat. Because of the varying requirements for every application, a length range for this technology is hard to define. We recommend discussing the specific needs for your part with our sales team to ensure all requirements of form, fit, and function will be properly addressed.